Application of CNC Angle Band Saw in H-beam Production Line

CNC angle band saws are mainly used for sawing workpieces with cross-sections such as H-shaped steel, channel steel, box beams, and round steel. They have superior performance, narrow sawing kerf, material saving, high sawing accuracy, high-power cutting, easy operation, real-time display of processing procedures and parameter information, intelligent and automated processing, and high production efficiency.

The cutting capacity of most CNC corner band saws on the market is below 1000mm, but the specifications of H-beams on the H-beam production line are relatively large. In order to solve the above problem, the Shanghai ANTISHICNC team customized a CNC corner band saw that can cut 1250mm high and 600mm wide H-beams for customers in need.

Product features:

1.Intelligent sawing control: The saw frame feed adopts hydraulic servo proportional valve and encoder, which can realize digital feeding, and can realize fast feeding, slow feeding and fast feeding for the workpiece.

2.The touch screen of the sawing machine can input the workpiece parameters in advance, and the sawing machine will automatically adjust the working process according to the input workpiece parameters; the processing parameter information data can be displayed and monitored in real time by the display screen.

3.The sawing machine is equipped with a saw blade break detection device. If the machine tool has an adverse condition or failure, the machine tool will automatically sense and stop.

4.The corner band sawing machine can automatically reduce or increase the sawing feed speed level according to the differences in workpiece specifications and materials.

5.The rotating worktable adopts a gantry structure with good rigidity, strong stability and flat sawing section.

6.The band saw blade is hydraulically tensioned, and the blade maintains good tension during rapid movement, which prolongs the life of the blade. Users can adjust the pressure according to the size of the steel section;

7.In order to ensure the reliability of the machine operation, the saw blade, guide rail, inverter, and hydraulic components on the band saw machine are all high-quality products of internationally renowned brands.

8.This production line can use CNC trolley feeding to achieve precise positioning of the workpiece.

Parameter:

| Model | SR1250 |

| Dimensions for H-Beams

Web height x flange width (mm) |

Max 1250*600, Min80*80 |

| Max. Cutting size when in 0°(mm) | 1250×600 |

| Max. Cutting size when in ±60 °(mm) | 500×600mm |

| Saw blade size (mm) | 9300×67×1.6 |

| Saw blade linear speed (m/min) | 20~150 (Variable frequency stepless speed regulation) |

| Tension mode of saw blade | Hydraulic |

| Host motor power (kW) | 15 kW 380V 50HZ |

| Hydraulic motor power (kW) | 5.5 kW 380V 50HZ |

| Work clamp | Two sets of hydraulic clamp (two groups) can be operated separately |

| Adjustment angle | -60°~0°~+60° Parametric control |

| Angle of saw band | 4° |

| Table height (mm) | 800 |

| Saw blade guide alloy | Hydraulic |

| Guide arm | Hydraulic move |

| Hydraulic pressure (MPa) | 6 |

| Hydraulic oil tank volume (L) | 100 |

| Feeding mode | CNC carriage feeding |

| Feeding speed | 0~20m/min |

| Main drive mode | Helical gear reducer |

| Overall dimensions of machine | About 4900mmx3000mmx3450mm |

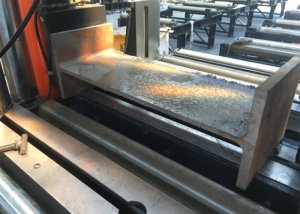

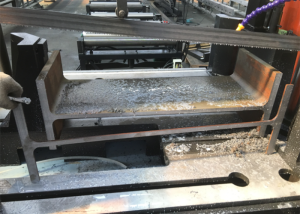

Cutting display:

|

|

|

|

|

|

If you have any needs for large H-beam cutting, please contact the Shanghai ANTISHICNC team and we will have someone to provide you with a solution. Please send an email to: saw@antishicnc.com