Application of Metal Band Saw in Automobile Manufacturing Industry

With the rapid development of the automobile manufacturing industry, the requirements for parts processing accuracy and efficiency are constantly increasing. As an efficient and precise cutting equipment, metal band saws play an increasingly important role in the automobile manufacturing industry.

Metal band saws are widely used in various production links of the automobile manufacturing industry, mainly including:

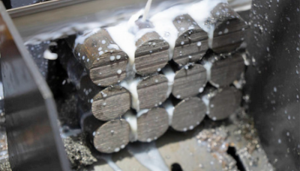

Raw material cutting: Used to cut metal plates, pipes, bars and other raw materials required for automobile bodies, chassis, engines and other parts. Compared with traditional gas cutting, plasma cutting and other methods, metal band saws have higher cutting accuracy, smoother cuts, and smaller heat-affected zones, effectively reducing subsequent processing procedures.

Parts processing: Used to process automobile parts such as gears, bearings, connecting rods, crankshafts, etc. Metal band saws can achieve precise cutting of complex shapes to meet the high-precision and high-strength requirements of automobile parts.

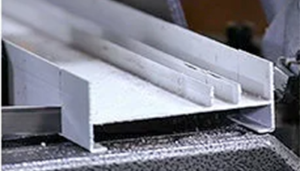

Mold manufacturing: Used to process automobile molds, such as stamping molds, casting molds, etc. Metal band saws can efficiently cut high-hardness materials such as mold steel to meet the high-precision and high-efficiency requirements of mold manufacturing.

Metal band saws are widely used in the automobile manufacturing industry, mainly due to their following advantages:

High precision: Using advanced CNC systems and servo motors, high-precision cutting can be achieved to meet the strict requirements of automotive parts for dimensional accuracy.

High efficiency: Fast cutting speed and high production efficiency can effectively shorten the production cycle and improve production efficiency.

Low cost: Compared with other cutting methods, the cutting cost of metal band saw is lower, which can effectively reduce production costs.

Environmental protection and energy saving: Adopting dry cutting method, no need to use coolant, more environmentally friendly and energy-saving.

Simple operation: The operation interface is friendly, easy to learn and operate, and reduces the technical requirements for operators.

|

|

|

|

|

|

|

|

| Technical Specifications | H-65N |

| Cutting capacity 0° (flat) (length x width) | ●650mm ■650×650mm |

| Band saw blade cutting line speed | 18-60 (frequency conversion) m/min |

| Clamping method | Hydraulic |

| Feed speed adjustment mode | Hydraulic stepless speed regulation |

| Saw blade size | 1.6×54×6530mm |

| Saw blade tension type | Hydraulic |

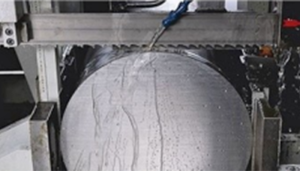

| Saw blade lubrication method | Emulsion spraying |

| Main motor power | 7.5kw-6p |

| Hydraulic motor power | 1.5kw |

| Cooling motor power | 0.09KW |

| Maximum length of one-way feeding | 500mm |

| Number of processing size setting groups | 1~5 groups |

| Maximum length of feeding material per group | 50000mm |

| Setting processing quantity per group | 1~999 pieces at a time |

| Setting sawing length control accuracy | ±0.2mm |

| Overall dimensions (length x width x height) | 3100mm×3000mm×2400mm |

| Weight(NET WEIGHT) | 1650kgs |

| Machine input power voltage | A.C380V, 50HZ |

| Hydraulic tank capacity | 100L |

| Cooling tank capacity | 80L |

|

|

If you are also in the automotive manufacturing industry, need to cut raw materials, process parts or mold manufacturing, and are looking for a suitable fully automatic metal band saw, welcome to consult Shanghai Antis. We are a senior band saw equipment supplier, with rich experience in mechanical equipment manufacturing and application, and can provide you with professional technical support.

Keywords: Metal Band Saw Machine, Fully Metal Automatic Band Saw Machine, Band Saw Machine