Application of Metal Band Saw in Bridge Construction

With the acceleration of global infrastructure construction, bridge engineering has increasingly stringent requirements on material processing efficiency and precision. Metal band saws have gradually become one of the key equipment in the field of bridge construction due to their efficient and precise cutting capabilities.

Core application scenarios of metal band saws in bridge construction

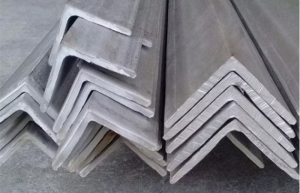

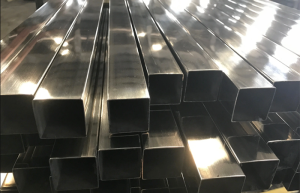

Bridge engineering involves the processing of a large number of high-strength metal materials, from steel beams, steel plates to special alloy components. Metal band saws play an important role in the following links due to their wide adaptability and high cutting efficiency:

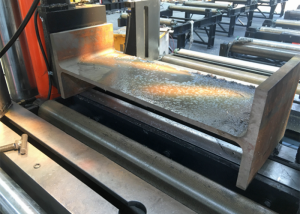

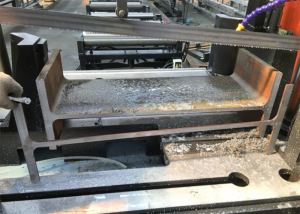

1.Large steel structure cutting

Modern bridges are mostly designed with steel structures, such as main beams, pier supports, etc. Metal band saws can efficiently cut steel plates or H-shaped steel with a thickness of more than 300mm, with high verticality of the cut (error less than 0.1mm/m), significantly reducing subsequent welding or grinding processes. For example, in the construction of the Hong Kong-Zhuhai-Macao Bridge, metal band saws were used to process super-large steel box beams to ensure that the dimensional accuracy meets the millimeter-level error requirements.

|

|

|

|

|

|

|

|

|

2.Processing of complex and special-shaped components

The cable anchors, connection nodes and other components of cable-stayed bridges and suspension bridges have complex shapes, and it is difficult to ensure the accuracy of traditional flame cutting. Metal band saws can achieve multi-angle and curve cutting through CNC programming. For example, in the Nanjing Yangtze River Fifth Bridge project, curved and special-shaped steel plates were successfully processed, and the efficiency was increased by 40% compared with traditional processes.

|

|

|

|

3.High-strength material processing

High-strength steels such as Q345B and Q420, and even special materials such as titanium alloys, are often used in bridge projects. Metal band saws are equipped with carbide blades or bimetallic blades, which can complete cutting under low vibration and low heat impact conditions to avoid damage to the internal structure of the material.

|

|

|

|

Technical advantages of metal band sawing machines

Compared with traditional cutting equipment (such as flame cutting and grinding wheel cutting), metal band sawing machines have significant advantages in bridge engineering:

| Comparison dimensions | Metal band sawing machine | Traditional cutting method |

| Cutting accuracy | ±0.1mm/m, no secondary processing required | ±1mm/m, requires grinding and correction |

| Material utilization | Saw kerf is only 1.5-2mm, saving materials | Saw kerf reaches 3-5mm, significant waste |

| Energy consumption and environmental protection | Dry cutting, no smoke and dust pollution | Flame cutting produces waste gas and noise |

| Degree of automation | Supports CNC programming, unmanned operation | Depends on manual operation, low efficiency |

Case: In the Shenzhen-Zhongshan Link project, a certain section used a cluster of fully automatic metal band saws, which could cut 120 tons of steel per day, reducing labor costs by 60% and shortening construction time by 15%.

With its precision, efficiency and environmental advantages, metal band saws are becoming an indispensable “steel tailor” in the field of bridge construction. With the in-depth application of intelligent and green technologies, this equipment will further promote bridge engineering to move towards high quality and sustainability. In the future, we may see metal band saws create more miracles in super projects such as cross-sea bridges and suspended bridges.

| Model | THSR1250 |

| Dimensions for H-Beams

Web height x flange width (mm) |

Max 1250*600, Min80*80 |

| Max. Cutting size when in 0°(mm) | 1250×600 |

| Max. Cutting size when in ±60 °(mm) | 500×600mm |

| Saw blade size (mm) | 9300×67×1.6 |

| Saw blade linear speed (m/min) | 20~150 (Variable frequency stepless speed regulation) |

| Tension mode of saw blade | Hydraulic |

| Host motor power (kW) | 15 kW 380V 50HZ |

| Hydraulic motor power (kW) | 5.5 kW 380V 50HZ |

| Work clamp | Two sets of hydraulic clamp (two groups) can be operated separately |

| Adjustment angle | -60°~0°~+60° Parametric control |

| Angle of saw band | 4° |

| Table height (mm) | 800 |

| Saw blade guide alloy | Hydraulic |

| Guide arm | Hydraulic move |

| Hydraulic pressure (MPa) | 6 |

| Hydraulic oil tank volume (L) | 100 |

| Feeding mode | CNC carriage feeding |

| Feeding speed | 0~20m/min |

| Main drive mode | Helical gear reducer |

| Overall dimensions of machine | About 4900*3000*3450mm |

If you are also in the field of bridge construction, need to cut large steel structures, process complex special-shaped components or need to process high-strength materials, and are looking for a suitable metal band saw, please contact Shanghai Antis. We are a senior band saw equipment supplier with rich experience in mechanical equipment manufacturing and application, and can provide you with professional technical support.