Application of Metal Band Saw in Metal Construction

Metal buildings are becoming the mainstream choice for modern industrial plants, stadiums, and high-rise buildings due to their high strength, fast construction, and recyclability. As core processing equipment, metal band saws are reshaping the efficiency of the entire metal building chain from material processing to construction with their high precision, low loss, and intelligent features.

Ⅰ.Core application scenarios in the field of metal buildings

Metal buildings need to process a large amount of steel, aluminum and composite metal materials. Metal band saws become “invisible pushers” in the following links:

1.Steel structure skeleton cutting

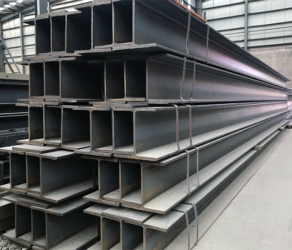

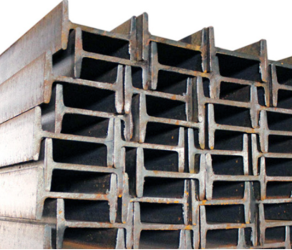

H-shaped steel and I-beam processing: The load-bearing skeleton of large venues needs to accurately cut H-shaped steel (such as Q355B material). Metal band saws can achieve one-time molding of super-large components with a length of 30 meters and a cross-section of 500mm×300mm, and the end face verticality error is ≤0.1mm/m, which directly meets the bolt hole assembly requirements.

Special-shaped connector manufacturing: For complex nodes of spatial grid structures, CNC band saws complete three-dimensional curved surface cutting through multi-axis linkage. For example, in the steel node processing of the Beijing Daxing Airport terminal, the band saw shortened the traditional 72-hour processing cycle to 18 hours.

|

|

|

|

2.Production of metal curtain walls and decorative components

Artistic modeling of aluminum plates and stainless steel: The metal band saw is equipped with ultra-fine tooth saw blades, which can cut decorative plates with a thickness of 0.5-50mm, and achieve fine processing such as hollow patterns and curved edges. The aluminum panels on the facade of the Dubai Museum of the Future use this technology, with no burrs on the cuts and the surface can be directly sprayed.

Composite sandwich panel processing: For metal-honeycomb aluminum composite panels, the band saw uses constant tension control technology to avoid delamination, and the cutting efficiency is 3 times higher than that of water jets, and the cost is reduced by 60%.

|

|

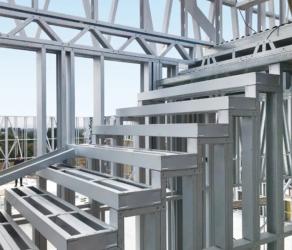

3.Modular building prefabricated parts processing

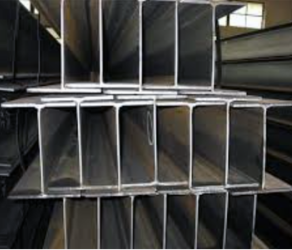

Container house frame cutting: Modular buildings require batch cutting of standard size steel components. The fully automatic band saw cluster can achieve continuous cutting of 150 square tubes (100mm×100mm) per hour with an accuracy error of ±0.3mm, meeting the needs of rapid assembly.

Light steel keel forming: In the residential light steel structure system, the band saw can process galvanized steel strips and cold-bent thin-walled profiles at the same time, with a cut flatness of Ra6.3μm, without the need for secondary grinding.

|

|

Ⅱ.Technical advantages: from material saving to green construction

Compared with traditional cutting processes, metal band saws bring multi-dimensional breakthroughs to the field of metal construction:

| Dimensions | Metal band saw | Traditional processes (such as plasma cutting) |

| Material utilization | The sawing seam is only 1.2-2mm, saving 5%-8% of materials | Saw seams of 3-5mm, significant material waste |

| Energy efficiency | The average power is 15kW, and the energy consumption is reduced by 70% | Plasma cutting machine power reaches 80-120kW |

| Environmental protection | Dry cutting, no smoke, no slag | Produces harmful gases such as ozone and nitrogen oxides |

| Scenario adaptability | The movable design supports on-site cutting | Relies on fixed plants and large energy supplies |

Typical case: In a prefabricated building industrial park in Shanghai, a production line consisting of 20 CNC band saws processes 20,000 tons of steel structures per month, reducing labor costs by 45% and material loss rate from 4.5% to 0.8%.

Metal band saws are redefining the possibilities of metal buildings with “millimeter-level precision and ton-level efficiency”. From the curved steel structures of landmark venues to the rapid modular houses for post-disaster emergency response, this technology not only improves the quality of buildings, but also promotes the industry’s transformation to intelligence and greenness. In the future, with the deep integration of new materials and digital technologies, metal band saws may become one of the core equipment in the era of “Construction Industry 4.0”.

Parameter reference:

| Technical Specifications| Model | 530A |

| Cutting capacity 0° (flat) (length x width) | 530*530 mm |

| Cutting capacity 0° (round) | 530 mm |

| Cutting capacity 0° (square) | 530*530 mm |

| Cutting speed infinitely variable | 25/55/85 m/min |

| Stop length(single stroke) | 500 mm |

| Accuracy of the feeding(single feeding) | ±0.2 mm |

| Saw blade size | 41*1.3*6240 mm |

| Saw blade tension type | Manual |

| Workbench height | 785 mm |

| Motor rating main drive | 7.5 kw |

| Motor rating of hydraulic feed | 1.5 kw |

| Overall dimensions (length x width x height) | 3300*2000*2000 mm |

| Weight(NET WEIGHT) | 3700 kgs |

|

|

If you are also in the metal construction industry, need to cut large steel structures, process complex special-shaped components or need to process high-strength materials, and are looking for a suitable metal band saw, please contact Shanghai ANTISHICNC Machine. We are an experienced band saw equipment supplier with rich experience in mechanical equipment manufacturing and application, and can provide you with professional technical support.