Band Saw Machines: Affordable Plate Cutting Machines

Medium thickness plate is a commonly used metal sheet that is suitable for a wide range of applications due to its moderate thickness. Medium-thickness plates have a wide range of uses in various industrial fields, and their high strength, corrosion resistance and workability make them indispensable materials in the manufacture of various structures and equipment. With the development of industry and technological progress, the application fields of medium thick plate are also expanding and deepening. There are also various cutting methods for medium thick plate, so which cutting method is the most economical in the case of limited budget?

Recently, ANTISHICNC received an inquiry from an Egyptian machinery company to cut a large steel plate of 2000-4000 mm length, 210 – 610 mm width and 20-30 mm thickness into smaller plates of 300-800 mm length, 100 mm width and 20-30 mm thickness.

The customer had a limited budget and a band saw was the best solution. At first, we recommended vertical saws + horizontal band saws, and then we recommended G5325(4M) vertical band saws + CS280II, which is the most convenient solution for cutting. The machine parameters are as follows:

| Picture |  |

|

|

| Model | G5325/35/400 | CS-280II | |

| Max.cutting

capacity |

Height 250mm | Round 280 mm

Quadrate 220*300 mm |

|

| Throat 350mm | |||

| Length 4000mm | |||

| Saw blade | Speed | 20/45/90m/min | 25/35/45/60/80 m/min |

| Size | 34×1.1mm | 27×0.9×3505 mm | |

| Tension | Manual | Manual | |

| Guides | Carbide and bearing blade guides | Carbide and bearing blade guides | |

| Cleaning | Wire brush & flood coolant | Wire brush & flood coolant | |

| Motor output | Blade | 2.2kw | 2.2 kw |

| Coolant | 60w | 60w | |

| Feed | 0.85kw(Servo motor) | / | |

| Main drive | Gear reducer | Gear reducer | |

| Vice | T-slotted table option with mechanical top clamp | Hydrualic | |

| Work feeding | Manual | Manual | |

| Standard Equipment: | |||

| 1. Blade cleaning brush. | |||

| 2. Working light. | |||

| 3. One piece of bi-metal saw blade. | |||

| 4. One set of tools with tool box | |||

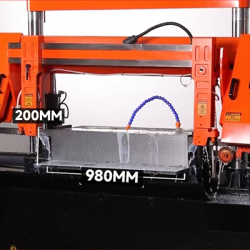

This solution is the most convenient solution, but the customer’s budget is limited, so we recommend the second solution for the customer, using our H-40/105S horizontal band saw machine to cut twice, the customer’s request is to cut the length of 2000-4000 mm, width of 210 – 610 mm, thickness of 20-30 mm large steel plate into 300-800 mm long, 100 mm wide, 20-30 mm thick small steel plate. 20-30 mm thick. The first time the plate is cut to the length of 300-800 mm required by the customer, then it is cut again on this machine in the other direction to a width of 100 mm.

The parameters of the machine are as follows:

| Picture |  |

| Technical Specifications | H-40/105S |

| Cutting capacity 0° (flat) (length x width) | ●400mm ■400×1050mm |

| Cutting speed | 20/36/57 m/min |

| Feed speed adjustment | Hydraulic stepless speed control |

| Clamping method | Hydraulic clamping |

| Saw blade size | 54×1.6×6170mm |

| Band saw blade tensioning method | Manual tensioning/relaxation |

| Saw belt lubrication method | Adopt emulsion spraying method |

| Main motor power | 5.5kw-6P (50 turbine box) |

| Hydraulic motor power | 0.75Kw |

| Coolant motor power | 0.09Kw |

| Machine input power voltage | A.C380V, 50HZ |

| Hydraulic tank capacity | 75L |

| Cooling tank capacity | 40L |

| Weight(NET WEIGHT) | 1906.5kgs |

| Machine size | 3140mm×1160mm×1780mm |

This option is not as convenient as the previous one, but it is a good choice when the budget machine is limited. In the end, the customer chose our second option.

Cutting display

|

|

If you also have metal cutting needs, welcome to contact the Shanghai Anticipation team, we have a dedicated docking, according to your actual situation to provide you with the optimal program.