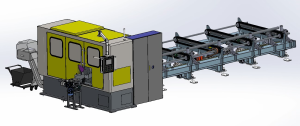

Fully automatic pipe cutting circular saw machine:cutting pipe / profile application case

Working Principle

The fully automatic high-speed pipe cutting circular saw machine mainly drives the circular saw blade to rotate at high speed through the motor. When the pipe is transported to the cutting position by the feeding device, the rotating saw blade cuts into the pipe under the action of power to achieve the cutting of the pipe. In this process, the high-speed rotation of the saw blade can quickly remove the pipe material, and its cutting speed is usually much faster than that of ordinary sawing machines. At the same time, the automated control system accurately controls the feed amount of the saw blade and the feeding length of the pipe to ensure the accuracy and efficiency of the cutting.

Functional introduction

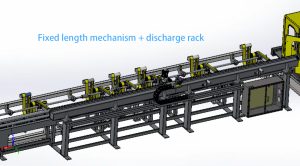

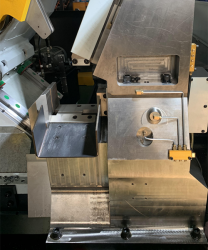

1.Overall composition of the equipment: fully automatic loading rack + high-speed circular saw machine mainframe + automatic chip removal mechanism; the circular saw machine mainframe is mainly composed of the equipment body bed, servo feeding mechanism, servo feeding device, gearbox, hydraulic clamping mechanism, lubrication system, automatic material distribution mechanism, saw blade residue chip removal mechanism and complete electrical system;

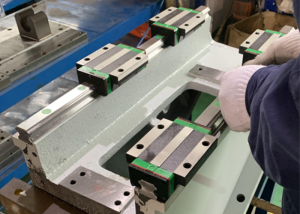

2.Machine bed: The whole bed is welded with high-quality steel plates, which are tempered after welding. It is a key component of machine tool equipment and has the characteristics of good overall rigidity, high strength, impact resistance, small deformation, and outstanding shock absorption performance. It can significantly improve the overall rigidity of the machine tool and the stability and reliability of the machine tool sawing;

3.Automatic feeding system: Manually hoist the whole bundle of materials to the automatic feeding rack to unwind and flatten, the equipment automatically loads and changes materials, and no manual intervention is required during the operation;

4.The servo automatic feeding mechanism of the equipment controls the feeding length through the servo, and the hydraulic clamping workpiece automatically feeds the material. The feeding accuracy is high, and the feeding stroke can be customized according to the customer’s actual sawing workpiece length range requirements. Extended feeding stroke;

5.The cutting workpiece adopts servo feeding sawing, and the saw blade adopts European advanced technology rail-type horizontal sawing, and the feeding speed can be set at will according to the cutting material. , the saw blade speed is infinitely variable, the cutting efficiency is high, and the sawing precision is higher;

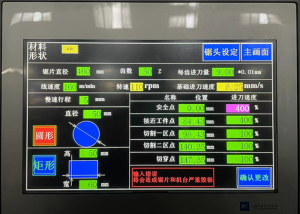

6.The humanized operation interface design makes the operation simpler and easier to understand. The software system function is more powerful than other brands, and the dynamic feed sawing function can be set according to the customer’s cutting material;

7.The micro-oil mist lubrication system lubricates and cools the saw blade head part with micro-oil mist during sawing to ensure the service life of the saw blade and the smoothness of the sawed workpiece. The amount of oil can be set at will according to the cutting requirements of the workpiece;

8.The settable timed lubrication system, the key transmission part of the equipment is equipped with an automatic timed centralized lubrication system, and the lubrication frequency and oil amount can be set at will according to the needs;

Application fields

1.Construction industry

It is used to cut various pipes for construction, such as water supply and drainage pipes (PVC pipes, PPR pipes, etc.), heating pipes (steel pipes, copper pipes, etc.). In construction, a large number of pipes of different lengths are required. The fully automatic high-speed pipe cutting circular saw can efficiently and accurately complete the cutting task and improve construction efficiency.

2.Automobile manufacturing industry

Many parts of automobiles are made of pipes, such as automobile exhaust system pipes, hydraulic system pipes, etc. This circular saw can meet the high-precision and high-quality cutting requirements of automobile parts, ensuring the performance and quality of automobile parts.

3.Furniture manufacturing industry

In furniture production, some metal pipes are used to make furniture frames, such as legs and armrests of metal tables and chairs. The fully automatic high-speed pipe cutting circular saw can quickly cut the pipes into suitable lengths, and can be mass-produced according to the different requirements of furniture design.

4.Mechanical processing industry

Cutting various pipe raw materials for mechanical processing, such as seamless steel pipes, alloy steel pipes, etc. After cutting, these pipes can be further processed into various mechanical parts, such as bushings, cylinders, etc.

Recently, Shanghai ANTISHICNC Machine received an inquiry from a Belarusian customer who needed a fully automatic pipe cutting machine. The customer’s requirements are as follows:

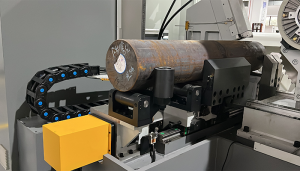

Cutting diameter: round workpieces from Ф70 to Ф210 mm; square workpieces in the range of 60-180 mm

Cutting materials: (mainly steel – ШХл5, ШХ15СГ, ШХ20, ШХ20СГ, SSCMA, 65G, X18H9T, 95Х18-Ш, 12Xl3) for forging/stamping workpieces,

Workpiece length: 2000-6000 mm minimum length of cutting part is 15 mm;

Feed error 30.1 mm; feed length (stroke) at least 800 mm; sawing speed requirement: 10-75 m/min

Customer material display

|

|

|

|

According to customer needs, we match the fully automatic pipe cutting circular saw machine CX260 model for customers

Model:CX260

|

|

|

|

|

|

Parameter Introduction

| Specific parameters | Model:CX260 |

| Maximum cutting capacity● | 70-210 mm |

| Maximum cutting capacity □ | 60-180 mm |

| Head spindle | |

| Applicable TCT alloy circular saw blade | Φ840 x 4.0 x 80 mm |

| Saw blade speed range | 40~ 60 rpm / stepless speed change |

| Spindle drive motor | 30 kW |

| Tool clearance compensation device | With brake to eliminate backlash |

| Tool anti-vibration parallel block | Tungsten carbide |

| Tool debris removal | Round steel brush |

| Cut-off feeding method | Heavy duty linear guide horizontal feed sawing |

| Clamping method | Hydraulic / horizontal and vertical set |

| Servo feeding + fixed length mechanism | |

| Feeding drive mode | Servo motor / precision ball screw |

| Feeding clamp mode | Horizontal hydraulic type |

| End cutting length | 8 ~ 99 mm arbitrary setting |

| Residual material length | ≥140mm + 1 workpiece length |

| Servo feeding stroke | Circular saw machine single 480 mm + fixed length mechanism single 6000mm |

| Automatic feeding device | |

| Material length | 6M |

| Feeding method | Hydraulic lifting |

| Hydraulic device | |

| Hydraulic drive motor | 5.5kW / 4p |

| Hydraulic drive pressure | 150 kg/cm² (8 MPa) |

| Hydraulic oil capacity | 150 liters |

| Air pressure device | |

| Working air pressure | 4 ~ 6 kg/cm² (55 ~ 85 psi) |

If you also need a suitable metal automatic pipe cutting circular saw machine, please consult Shanghai ANTISHICNC. We are senior metal processing equipment supplier with rich experience in mechanical equipment manufacturing and application, and can provide you with professional technical support.