Fully automatic pipe cutting machine – copper pipe cutting

Fully automatic pipe cutting machine is an automated equipment for cutting pipes.

1.Basic principle

It mainly uses the control system to command the power device to drive the cutting tool and cut the pipe according to the set parameters. During the working process, the motor provides power to drive the cutting tool to rotate. At the same time, the pipe will move towards the cutting tool at a stable speed under the push of the feeding device. When the pipe reaches the preset cutting length or cutting position, the cutting tool will cut the pipe under the command of the control system.

2.Main components

Cutting system

The cutting tool is the core component, and its material and shape vary according to the material of the pipe (such as metal pipe, plastic pipe, etc.) and cutting requirements (such as cutting accuracy, pipe thickness, etc.). For example, when cutting metal pipes, carbide tools are usually used because the metal hardness is high and this tool can ensure the cutting accuracy and the service life of the tool.

The rotation speed of the tool can be adjusted. For thicker pipes, a lower rotation speed is required to ensure cutting quality and avoid excessive wear of the tool; for thinner pipes, the rotation speed can be appropriately increased to improve cutting efficiency.

Feeding system

The feeding device is responsible for accurately conveying the pipe to the cutting position. Its accuracy has a crucial impact on the length accuracy of the cut pipe. Generally, high-precision rollers or conveyor belts are used to accurately control the feeding amount of the pipe through servo motors or stepper motors. For example, in some high-demand pipe processing scenarios, the feeding accuracy can reach ±0.1mm or even higher.

There will also be a pipe clamping device to ensure that the pipe does not move during the feeding and cutting process. This clamping device can be adjusted according to the shape and size of the pipe and can firmly clamp the pipe. For example, for round pipes, a round clamping block will be used to fit the surface of the pipe for clamping.

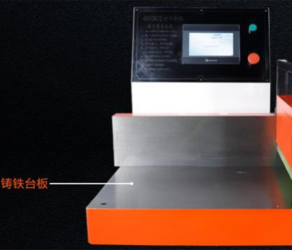

Control system

This is the “brain” of the fully automatic pipe cutting machine. It can be a control system based on PLC (programmable logic controller) or industrial computer. The operator can enter cutting parameters such as pipe length, cutting speed, cutting quantity, etc. through the operation panel or software interface.

The control system also has automatic diagnosis and alarm functions. For example, when the tool is severely worn or the pipe conveying is abnormal, the system will automatically detect and send out an alarm signal, prompting the operator to perform maintenance or adjustments.

3.Advantages

High-precision cutting: It can accurately control the cutting length and cut quality of the pipe, and the cut is smooth and vertical. For example, in the furniture manufacturing industry, for the cutting of metal pipes, the fully automatic pipe cutting machine can ensure that the length error of the pipe after cutting is within a very small range, which is conducive to the subsequent assembly work.

High degree of automation and efficiency: It can automatically complete a series of operations such as feeding and cutting of pipes, reducing the manual operation links and greatly improving production efficiency. Compared with traditional manual cutting or semi-automatic cutting equipment, it can cut more pipes per unit time. And it can work continuously, only regular maintenance and replenishment of pipes are required.

High safety: Since the operator does not need to directly contact the cutting tool and the pipe being cut, the risk of injury to the operator is reduced. The equipment usually has protective devices, such as protective doors, light curtain sensors, etc. When the protective device is triggered (such as opening the protective door), the equipment will automatically stop running to ensure the safety of the operator.

4. Application fields

Construction industry: used to cut various metal pipes (such as steel pipes) and plastic pipes (such as PVC pipes), which can be used in the water supply and drainage system, heating pipe system, etc. of the building.

Automobile manufacturing industry: cutting pipes in automobile parts, such as metal pipe brackets of car seats, etc., requires high cutting accuracy and efficiency.

Furniture manufacturing industry: cutting metal or wooden pipes for making bracket parts of furniture such as tables, chairs, beds, etc., which can meet the cutting needs of different sizes and shapes.

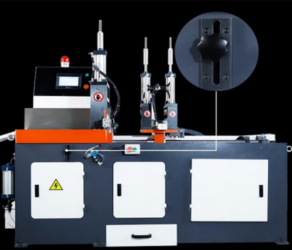

Recently, Shanghai ANTISHICNC Machine received a request from a Greek customer for a fully automatic pipe cutting machine, which mainly cuts copper solid bars/copper tubes/aluminum tubes. The maximum length of the tube is 6000mm, and the maximum length of the bar is 4000mm; the maximum diameter of the workpiece is 80mm, and the minimum diameter is 3mm; the maximum length after cutting is 750mm, and the minimum length is 80mm; according to the customer’s needs, we matched the customer with the fully automatic pipe cutting machine model 455, as shown below:

| 455 fully automatic pipe cutting machine | |

|

|

|

|

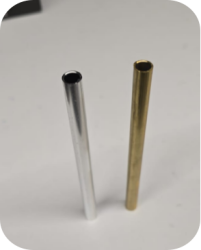

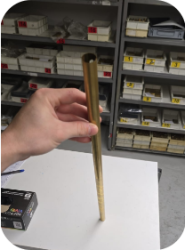

Customer’s actual workpiece image

|

|

|

|

The matching parameters are as follows:

| Model | 455CNC |

| Cutting Angle | 90° |

| Maximum cutting height | 120mm |

| Maximum cutting width | 240mm |

| Cutting capacity round tube | 110mm |

| Cutting ability square tube | 110*110mm |

| Cutting capacity solid square bar | 90*90mm |

| Cutting capacity solid round bar | 100mm |

| Power of servo motor | 0.75KW |

| Single feeding travel | 6-700mm |

| Feeding accuracy | ±0.05mm |

| Machine Dimension | 1950*1300*2000mm |

| Machine weight | 850kg |

If you also need a suitable metal automatic pipe cutting machine, please consult Shanghai ANTISHICNC. We are a senior supplier of metal processing equipment, with rich experience in mechanical equipment manufacturing and application, and can provide you with professional technical support.

Keywords: Fully automatic pipe cutting machine, Metal fully automatic pipe cutting machine, Fully automatic cutting machine