How does ANTISHICNC company flange circular sawing machine work?

With the development of national large assembly manufacturing industry, port equipment, wind power, oil and other industries. The demand for construction machinery, port equipment, wind power equipment and petroleum machinery is increasing, and the model specifications are also getting bigger and bigger. As the important parts of these equipment, the demand for flanges, pipe fittings and rings is also increasing. For example, the diameter of the ring for wind turbines can reach 8 meters. However, there is a problem that if a single ring is milled, there is a large machining allowance, and enough machining allowance is needed on both sides of the ring to ensure the size of the finished product. If the traditional vertical or horizontal band sawing machine is used for sawing, a 2-meter-diameter ring requires a G42200 circular sawing machine, and the sawing time is about 4 hours, which is inefficient, and at the same time, due to the large diameter of the saw, the sawing deviation is also large, resulting in a large amount of subsequent machining allowances. The ring and flange parts are small thickness but large diameter workpieces, no matter using vertical or horizontal band sawing machine, there are clamping difficulties. In order to solve the defects and shortcomings of the above existing technology, ANTISHICNC provides a kind of CNC sawing machine for flange parts with high structural reliability and stability, as well as high cutting precision, high cutting efficiency, simple operation and low sawing cost. The sawing machine is specially used for cutting off large ring-shaped pieces of pipe fittings and other hollow circular workpieces; the entire work process is automatically controlled, with fast cutting speed, high efficiency, easy and convenient operation, narrow saw kerf, material saving, energy saving and other advantages.

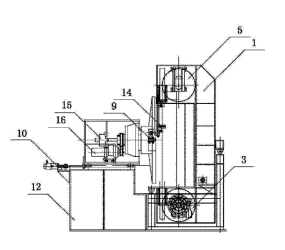

Structure of the circular sawing machine

The circular sawing machine includes a saw frame and a saw belt transmission system, the transmission system includes a main wheel, a tensioning wheel and a saw belt tensioning mechanism, the middle of the saw frame is equipped with a saw belt centering guiding device, and the side of the saw frame is equipped with a circular clamping rotary device, whose positioning surface is parallel to the saw belt. This circular sawing machine adopts the parallel cooperation between the circular clamping rotating device and the sawing belt on the saw frame, which makes its structure reliable and stable, with high cutting precision, and can adjust the cutting speed and feed speed at will, meanwhile, it has high cutting efficiency, simple operation and low sawing cost. The saw frame is also equipped with a saw frame feeding device to control the position of the saw frame. The ring clamping rotary device is equipped with a lever-type ring tensioning device on one side, the other side is equipped with a rotary motor and a hydraulic rotary cylinder, the said lever-type ring tensioning device is equipped with three tensioning columns; the bottom is equipped with a ring moving device to control the position of the ring clamping rotary device; the lower part is equipped with a hydraulic system for controlling the hydraulic rotary cylinder, and the said saw frame is equipped with an electrical system and a cooling system on both sides respectively.

Work Principle

|

|

|

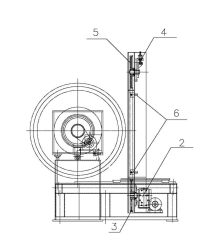

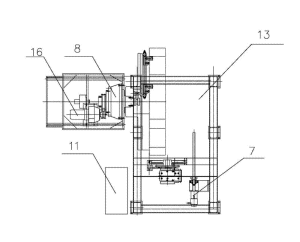

| Structural schmatic | side view | top view |

In the figure 1.saw frame, 2.saw belt transmission system, 3.active wheel, 4.saw belt tensioning device, 5.tensioning wheel, 6.saw belt centering guide device, 7.saw frame feeding device, 8.circular clamping rotary device, 9.lever type circular tensioning device, 10.circular moving device, 11.electrical system, 12.hydraulic system, 13.cooling system, 14.tensioning column, 15.hydraulic rotary cylinder 16.Rotary motor.

When this circular sawing machine works, the electrical system 11 and the hydraulic system 12 are started first, the distance between the saw belt centering guide device 6 is adjusted so that the distance is suitable for the size of the workpiece to be sawed, the saw belt is tensioned on the active wheel 3 and the driven wheel 5 of the transmission system 2 of the saw frame 1 through the saw belt tensioning device 4, and the saw frame feeding device 7 is started to back off the saw frame 1 to the starting position, and the circular moving device 10 is started to back off the saw frame 1 to the starting position. The workpiece is then lifted onto the three tensioning columns 14 of the lever-type circular tensioning device 9, and the three tensioning columns 14 are driven by the hydraulic rotary cylinder 15, which tension the workpiece on the tensioning columns 14 to facilitate rotary sawing. Then activate the ring moving device 10, the workpiece will be moved to the required sawing position and the saw belt position line coincidence. The rotary motor 16 of the ring clamping rotary device 8 is activated and the ring clamping rotary device 8 rotates at a speed regulated by the electrical system 11. Then start the saw belt drive system 2 and saw frame feeding system 7, the saw belt in the saw belt drive system 2 driven by the main wheel 3 rotary movement, saw frame feeding system 7 drive, drive the saw frame 1 forward feeding movement, and at the same time start the cooling system 13, the machine tool began to saw the workpiece. The rotating speed of the ring, the running speed of the saw belt and the feeding speed of the saw frame can be steplessly adjusted by the electrical system 11. After sawing, the saw frame 1 automatically backs up, back in place, the saw belt drive system 2, the ring clamping rotary device 8 and the cooling system 13 stop working, and then loosen the lever-type ring tensioning device 9, remove the sawed workpiece, a sawing is completed.

Shanghai Ants Machine Equipment Co., Ltd. is a professional manufacturer in the field of metal cutting. Our company has developed and produced many varieties of metal cutting products such as metal band saw machine series, metal circular saw machine series, plate cutter series, graphite cutting series, sapphire cutting series, mold steel cutting series, flange saw series, etc. The products are widely used in aviation, auto parts, air-conditioning and refrigeration, bicycle, fitness equipment, steel furniture, building decoration industry and all industries using metal materials. Widely used in aviation, auto parts, air conditioning and refrigeration, bicycles, fitness equipment, steel furniture, construction and decoration industry and all industries that use metal materials. We are in the leading position among our counterparts in China. If you have any need in this area of manufacturers, you can contact Anticipation for further communication.