How to choose a suitable bandsaw machine

In modern industrial production, band saws as an important metal cutting equipment, its selection of the right or wrong directly affects the production efficiency and processing quality. So, how can you pick a sawmill that meets your needs?

First of all, we need to know what classification of sawing machine.

1.Classified according to the sawing method:

Band sawing machine: sawing through a circular sawing band, with high sawing precision and high efficiency.

Circular sawing machine: using circular saw blade for cutting, suitable for thicker material truncation.

Bow Sawing Machine: relies on the reciprocating motion of the saw bow to realize sawing.

2.Classified according to the degree of automation:

Manual Sawing Machine: manual operation is required to complete the sawing process, which is more labor-intensive.

Semi-automatic Sawing Machine: part of the operation is done automatically by the machine, such as knife feeding, clamping, etc., still need a certain degree of manual intervention.

Full-automatic sawing machine: the whole process from feeding to sawing and unloading etc. realizes automatic control and high production efficiency.

3.Categorized by structural form:

Horizontal Sawing Machine: Horizontal sawing machine is also divided into horizontal straight cutting and horizontal miter cutting (i.e. angle cutting); the saw frame is placed horizontally, usually applicable to sawing of large workpieces.

Vertical sawing machine: the saw frame is placed vertically, occupies a smaller area, and is suitable for the processing of small workpieces.

For example, in the machining workshop, for a large number of metal material cutting needs, usually choose fully automatic metal band sawing machine to improve productivity and accuracy; while in the small workshop, may choose manual small sawing machine to meet the needs of simple metal processing, mostly circular sawing machine.

Different types of sawing machines play their respective advantages in different industries and application scenarios, and the choice should be decided according to the specific processing requirements and conditions.

Secondly, we need to know which metal materials can be cut with a sawmill, including but not limited to the following:

1.Steel: such as carbon steel, alloy steel, stainless steel and so on. Carbon steel is commonly used in building structures and general machinery manufacturing; alloy steel has better performance in terms of strength, toughness and wear resistance, commonly used in automotive manufacturing, aerospace and other fields; stainless steel is commonly used in the chemical industry, food processing and other industries because of its corrosion resistance.

2.Aluminum: lightweight, corrosion-resistant features, widely used in aerospace, automotive manufacturing, electronic equipment and other fields.

3.Copper: including pure copper and various copper alloys, commonly used in electrical, electronic, piping and so on.

4.Titanium: with high strength, low density and good corrosion resistance, commonly used in aerospace, medical and other high-end fields.

5.Cast iron: such as gray cast iron, ductile iron, etc., commonly used in the manufacture of mechanical parts, engine block, etc..

Finally, if we are not sure what type of sawmill we need when choosing a bandsaw machine, we can quickly match it with the following table

| Please fill in the table with detail information or highlight your selection | ||||||

| Horizontal

Structure Metal Band Saw |

Cutting Material | Material Structure | Solid Bar/Hollow Pipe/ Rectangular/Square/Profile | |||

| Hardness (HRC) | Thickness

(if Pipe) |

|||||

| Max. Cutting Size

(diameter/width* height) |

Max. Cutting Section Length | Max. Length for the Raw Material | ||||

| Cutting times per Day | Automatic/Manual | Angle Cutting or Not | ||||

| Bundle Sawing or Not | Bundle Shape | Bundle Section Size | ||||

| Vertical Structure Metal Band

Saw |

Cutting Material | Cutting Direction

(horizontal/Vertical) |

||||

| Hardness (HRC) | Sawing Dimension

(height*length*width) |

|||||

| Max. Cutting Size

(diameter/width* height) |

Other Special Requirement | |||||

| Circular Saw Machine | Cutting Material | Material Structure | Solid Bar/Hollow Pipe/

Rectangular/Square/Profile |

|||

| Hardness (HRC) | Thickness(if Pipe) | |||||

| Max. Cutting Size

(diameter/width* height) |

Max. Cutting Section Length | |||||

| Cutting times per Day | Max. Length for the Raw Material | |||||

| Automatic Unloading Need or Not | Other Special Requirement | |||||

With the above expertise, you can quickly learn about sawmills and find the right model for you; The ANTISHICNC Team in Shanghai can offer a wide range of band sawmills to cover a wider range of workpieces.

| Technical Specifications| Model | 330A | 330B | 430A | 430B |

| Cutting capacity 0° (flat) (length x width) | 330*330mm | 330*330mm | 430*430mm | 430*430mm |

| Cutting capacity 0° (round) | 330mm | 330mm | 430mm | 430mm |

| Cutting capacity 0° (square) | 330*330mm | 330*330mm | 430*430mm | 430*430mm |

| Cutting speed infinitely variable | 25/45/64/80m/min | 20~80m/min | 18~80m/min | 18~80m/min |

| Accuracy of the feeding(single feeding) | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Saw blade size | 34*1.1*4115mm | 34*1.1*4115mm | 41*1.3*5080mm | 41*1.3*5080mm |

| Saw blade tension type | Manual | Hydrualic | Manual | Hydrualic |

| Workbench height | 685mm | 685mm | 745mm | 745mm |

| Motor rating main drive | 4kw | 4kw | 7.5kw | 7.5kw |

| Motor rating of hydraulic feed | 0.75kw | 0.75kw | 1.5kw | 1.5kw |

| Overall dimensions (length x width x height) | 2350*2220*1500mm | 2350*2220*1500mm | 2750*2250*1710mm | 2750*2250*1710mm |

| Weight(NET WEIGHT) | 1992kgs | 2054kgs | 2710kgs | 2778kgs |

How to choose the right sawing machine in ANTISHICNC, we can quickly match the above contents; for example, the model in the table below is the parameter introduction of our newest fully automatic sawing machine, you can also refer to it:

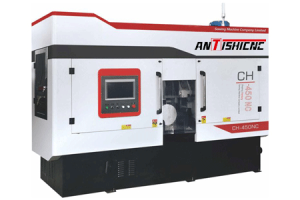

| Reference image of the bandsaw machine is displayed | |

|

|

|

|

As a supplier with more than 20 years of experience in the production of machine tools, Shanghai ANTISHICNC can quickly match you with the right machine after understanding your specific needs. If you need a band sawing machine, you can refer to our website: https://www.metalbandsawmachine.com/semi-auto-bandsaw/.

At the same time, our band sawing machine can be equipped with automatic feeding device, if necessary, welcome to consult us!