How to choose between horizontal and vertical graphite band sawing machine?

Graphite has the characteristics of high temperature resistance, thermal conductivity, plasticity and so on. People’s demand for mechanical processing is also increasing. At present, during the processing of graphite blocks, people usually need to manually debug the blocks, and manual debugging is not possible. The accuracy requirements are biased, and this type of band sawing machine is very large, and the time cost required after manual debugging also increases. Therefore, a band sawing machine that can automatically process is now needed. ANTISHICNC can provide graphite band saw machines with simple structure and automatic processing.

Graphite band sawing machines are all customized equipment. The cutting size range, performance configuration, CNC mode, load-bearing delivery, etc. of the sawing machine are all customized according to the needs of customers. The horizontal graphite band sawing machine is used for cutting small graphite workpieces, and the vertical graphite band sawing machine is used for cutting small graphite workpieces. Sawing machines are more suitable for slicing large graphite workpieces. Here are the main differences between horizontal and vertical band saws.

| The main difference between horizontal graphite band sawing machine and vertical graphite band sawing machine | |

|

Horizontal graphite band sawing machine with saw frame arranged horizontally or inclined, feeding along the vertical direction or the direction of swinging around a point, the saw blade ordinary change 40 ° to maintain the band saw blade teeth perpendicular to the workpiece, horizontal graphite band sawing machine with manual operation, semi-automatic operation, fully automatic operation mode, support for customized CNC graphite band sawing machine, high-speed graphite band sawing machine, graphite cutting customized sawing machine and so on, suitable for sawing different workpieces, functionality Diversified, can meet the differentiated sawing needs of most enterprises. |

|

Vertical graphite band sawing machine saw frame set vertically, the workpiece moves when sawing, used to cut sheet and molding parts of the curved profile, more suitable for high-volume, large workpiece production and processing, vertical graphite band sawing machine is usually customized to the CNC configuration based on the majority, if the buyer does not have a high demand for sawing accuracy, you can choose manual, semi-automatic configuration of the vertical graphite band sawing machine, if there is a high degree of precision, high efficiency of the production needs, should be Choose automatic vertical CNC graphite band sawing machine, vertical intelligent CNC graphite band sawing machine can be stable high-speed, high-precision continuous sawing, to meet the enterprise’s large-volume sawing efficiency, vertical CNC graphite band sawing machine for the production of large workpieces processing efficiency is ideal, more conducive to cost savings, and significantly improve the production efficiency of enterprises. |

For the cutting accuracy requirements are not high, the production volume is not large customers, semi-automatic mode of graphite band sawing machine can fully meet your cutting needs, the cost is also lower. On the contrary, there are high precision, high speed, high production demand for customers, should choose automatic CNC graphite band sawing machine, although the cost is slightly higher, but in order to ensure high speed and high precision at the same time, the production efficiency is more than semi-automatic sawing machine 3-5 times, automatic CNC mode of graphite band sawing machine cutting fine, can guard against waste of materials, is the right choice for mass production.

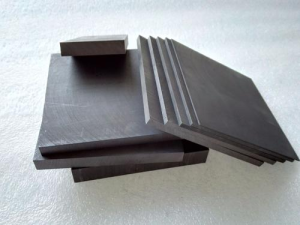

| Finished product display | |

|

|

In order to help enterprises save costs, ANTISHICNC suggests that customers in the purchase of graphite band sawing machine, first to determine their own production needs and purchase intention, there are special sawing requirements or sawing difficulties, summarized after providing to the manufacturer’s technical personnel, ANTISHICNC will be according to your specific needs for directional design and manufacturing.

ANTISHICNC company currently produced horizontal graphite band sawing machine, vertical graphite band sawing machine, high-speed graphite band sawing machine, intelligent CNC graphite band sawing machine, non-standard customized band sawing machine, and various types of band saws, etc., advanced technology, stable performance, equipped with perfect technical support and after-sales service, welcome to call us for advice and purchase!

Keywords: graphite band sawing machine, graphite cutting, carbon cutting, sawing machine