How to select and use a vertical metal band saw

Vertical metal band saw is a device used to cut metal materials. It is mainly composed of a bed, a saw frame, a saw band, a power system, a transmission system and a control system. The bed is the basic part of the entire equipment, providing stable support for the saw frame and other components. It is generally made of solid materials such as cast iron to reduce vibration during sawing. The saw frame is vertically mounted on the bed to tension and guide the saw band. The saw band is a key component for cutting. It is usually a circular steel belt with saw teeth on its edge. The width of the saw band and the shape of the saw teeth are designed according to different sawing requirements. The power system mainly includes a motor, which provides power for the operation of the saw band. The power of the motor will affect the cutting speed and cutting capacity of the saw band. The transmission system is responsible for transmitting the power of the motor to the saw band so that the saw band can run at a suitable speed and tension. Common transmission methods include gear transmission and belt transmission. The control system can adjust the speed, feed rate and other parameters of the saw band. Some advanced vertical metal band saws can also achieve automatic cutting. The selection and use of metal vertical saws need to consider multiple factors. The following are the details:

I. Selection points:

1.Cutting material characteristics

Material types:

The hardness of different metal materials varies greatly. For example, the hardness of ordinary carbon steel is relatively low, while the hardness of high-speed steel, carbide, etc. is very high. If you want to cut hard materials, such as carbide, you need to choose a metal vertical saw with a high-hardness saw blade. Carbide saw blades have good wear resistance and can withstand the high hardness of carbide while maintaining good cutting performance.

For non-ferrous metals, such as aluminum and copper, they are soft and have good ductility. When cutting these materials, it is easy for the material to stick to the saw blade. Therefore, you should choose a vertical saw with a suitable saw tooth shape, such as a saw blade with a bevel tooth design. This kind of saw blade can make it easier to discharge chips during cutting and prevent materials from accumulating on the saw blade and affecting the cutting quality.

Material size:

The thickness of the material is an important consideration. If you want to cut thicker metal sheets, such as steel plates with a thickness of more than 50mm, you need to choose a metal vertical saw with strong sawing ability and high power. Usually, the product manual of the vertical saw will indicate its maximum sawing thickness, for example, the maximum sawing thickness of a certain model of vertical saw is 100mm.

The width of the material will also affect the selection. For wider materials, you need to choose a vertical saw with a suitable blade length to ensure that the saw blade can completely cut through the material.

2.Cutting accuracy requirements

Precision processing occasions:

In fields with extremely high precision requirements such as precision machining and mold manufacturing, it is necessary to choose a metal vertical saw with a high-precision guide device. For example, some high-end metal vertical saws are equipped with linear guides, which can ensure that the straightness error of the saw blade during cutting is within a very small range, such as ±0.1mm/m. At the same time, the thickness tolerance of the saw blade of this type of vertical saw is also very small, thereby reducing the impact of the saw seam width on accuracy.

General processing occasions:

For situations where the precision requirements are not particularly high, such as cutting of building materials and general metal component processing, you can choose a metal vertical saw with ordinary precision. These vertical saws are relatively cheap, and their accuracy (such as the straightness error may be around ±0.5mm/m) can also meet most general cutting requirements.

3.Production efficiency requirements

High output requirements:

In a mass production environment, in order to improve efficiency, it is necessary to choose a metal vertical saw with a fast sawing speed. This is related to the motor power and saw blade design of the vertical saw. A motor with a higher power (such as 3kW or more) can provide a higher speed and torque, allowing the saw blade to cut materials quickly. At the same time, a saw blade with a multi-tooth design can remove more material per unit time, thereby improving sawing efficiency. For example, in the production of automotive parts, in order to meet the beat requirements of the production line, a high-speed and efficient metal vertical saw is often selected.

Small batch or occasional use:

For small batch production or occasional use, you can choose a metal vertical saw that is simple to operate and relatively affordable. The sawing speed of this type of vertical saw may not be the fastest, but it can meet basic cutting needs and is easy to maintain and operate.

4.Convenience of saw blade replacement

Considering that the saw blade will wear out during use, it needs to be replaced regularly. Therefore, it is necessary to choose a metal vertical saw with easy saw blade replacement. Some vertical saws have simple saw blade installation structures, and the saw blade can be replaced with a few screws or quick clamps, while some complex structures may require professional tools and a longer time to replace the saw blade.

5.Stability and durability of the equipment

The stability of the equipment is crucial to cutting quality and safety. Metal vertical saws with a sturdy body and a stable base can reduce vibration and ensure that the saw blade runs smoothly during cutting. For example, vertical saws with a heavy cast iron base have better stability.

In terms of durability, the quality of key components of the vertical saw, such as motors and transmission components, should be considered. Good quality motors have a long service life and can work stably for a long time without problems such as overheating. The quality of transmission components also affects the overall life of the equipment. For example, high-quality belt or gear transmission can ensure effective power transmission and reduce the probability of failure.

6.Demand for automation level

If automated cutting is required, such as in a CNC machining environment, it is necessary to choose a metal vertical saw that is compatible with the CNC system. These vertical saws can receive CNC instructions and accurately control parameters such as sawing speed, feed rate and cutting path to achieve efficient and accurate automated cutting.

For manual operation, more attention is paid to the convenience of vertical saw operation, such as whether the design of the operating handle is ergonomic, convenient for the operator to comfortably control the feed of the saw blade, etc.

7.Budget constraints

The price range of metal vertical saws is very wide, ranging from a few thousand yuan to tens of thousands of yuan. When selecting a model, you need to choose according to your budget. If the budget is limited, you can choose a vertical saw with relatively simple functions but can meet basic cutting needs. If you have high requirements for cutting quality, efficiency and accuracy, and have sufficient budget, you can choose a high-end metal vertical saw with multiple advanced functions.

|

|

|

| Vertical Metal Band Saw | Vertical Metal Band Saw | Vertical Metal Band Saw |

II.Usage

Install the saw blade

1.Check the saw blade

Before installing the saw blade, carefully check whether the saw blade is damaged, such as whether the saw teeth are broken, whether there are cracks on the surface of the saw blade, etc. If the saw blade is damaged, it will affect the sawing quality and the service life of the saw blade.

2.Installation steps

Install the saw blade according to the instructions of the vertical saw. Generally speaking, one end of the saw blade needs to be fixed to one end of the saw blade chuck of the vertical saw, and then the saw blade is tightened through the adjustment device. The tension should be moderate. Too loose will cause the saw blade to deviate and vibrate easily during the cutting process, affecting the cutting accuracy; too tight may cause the saw blade to break. For example, for some small metal vertical saws, after tightening the saw blade, flick the saw blade with your fingers and it will make a crisp sound, indicating that the tension is appropriate.

Adjust cutting parameters

1.Cutting speed

Adjust the cutting speed according to the type and size of the sawing material. Generally speaking, softer metal materials can use higher cutting speeds, while harder materials need to reduce the cutting speed. For example, when cutting aluminum alloy materials, the cutting speed can be set to 50-100 meters per minute; while when cutting high-hardness alloy steel, the cutting speed may be reduced to 10-30 meters per minute. The adjustment of cutting speed is usually achieved by changing the speed of the vertical saw motor. Some vertical saws are equipped with variable frequency speed regulation devices, which can easily adjust the speed.

2.Feed rate

The feed rate refers to the depth of the saw blade cutting into the material in each rotation or each reciprocating motion. The appropriate feed rate can ensure the cutting quality and the service life of the saw blade. If the feed rate is too large, it will cause the saw blade to be overloaded, which is easy to damage the saw blade, and the quality of the cutting surface will also deteriorate; if the feed rate is too small, it will reduce the cutting efficiency. For example, when cutting a steel plate with a thickness of 10mm, the feed rate can be set to 0.1-0.2mm per tooth. The feed rate is usually adjusted through the feed mechanism of the vertical saw. Some vertical saws are manually adjusted with the feed knob, while others are precisely controlled by the CNC system.

Safe operation

1.Personal protection

When using a metal vertical saw, the operator should wear protective glasses to prevent metal chips from splashing into the eyes during the sawing process. At the same time, wear work clothes and protective gloves to avoid scratches or burns on the hands. For example, when cutting high-temperature metal materials (such as metals that have just been heat-treated), gloves can prevent hands from being burned.

2.Fixing the workpiece

Fix the workpiece to be sawed firmly on the workbench to prevent the workpiece from moving during the cutting process, affecting the cutting quality and safety. You can use clamps (such as flat-nose pliers, pressure plates, etc.) to fix the workpiece. For larger workpieces, multiple clamps may be required to ensure their stability. For example, when cutting long metal profiles, use clamps at least at both ends to fix them.

3.Operating specifications

Before starting the vertical saw, check whether the saw blade is installed correctly and whether the cutting parameters are set reasonably. During the cutting process, do not touch the saw blade and the workpiece with your hands to prevent injury. If you find that the saw blade vibrates abnormally or makes abnormal sounds, stop cutting immediately and check the cause. After cutting, wait until the saw blade stops turning completely before cleaning the workpiece and work area.

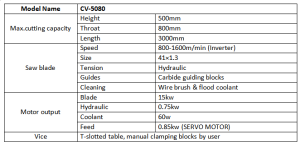

The following parameters can be used as reference

The above CV5080 model is used by customers to cut 3m*1.5m steel plates. For example, in the manufacturing process of steel structure buildings, large steel plates need to be cut into components of different shapes and sizes. The metal vertical saw cuts the steel plate with the saw teeth through the reciprocating motion of the saw blade according to the set cutting path. The reciprocating motion of the saw blade in its working principle can accurately control the cutting depth and cutting direction, so as to cut the steel plate into the required beams, columns and other components, and can ensure that the cutting surface is relatively flat to meet the connection requirements of the building structure.

If you need a suitable vertical metal band saw.Welcome to consult Shanghai ANTISHICNC Team. We are a senior supplier of vertical metal band saw, with rich experience in manufacturing and utilizing machinery and equipment, and can provide you with professional technical support.

Please send e-mail to: contact@antsmachine.com