Is it difficult to operate a fully automatic CNC bandsaw machine?

Automatic CNC band sawing machine is an advanced sawing equipment, its working principle mainly includes mechanical transmission and electrical control of two parts:

Mechanical transmission part: usually driven by the main transmission system saw blade sawing movement. The spindle of the main drive system is supported by high-precision bearings and fixed on the table, the spindle installed motor reducer, through the belt and other transmission methods to drive the table to rotate, so that the saw blade to realize the rotary cutting action.

Electrical control part: the control system is the core of the automatic CNC band sawing machine, including electrical control box (cabinet) and PLC programmable controller and other components. Through the input power supply voltage signal, current signal, etc., the control system outputs switching and analog quantities to accurately control the various actions of the equipment, such as saw blade feeding, speed adjustment, clamping device action, and so on.

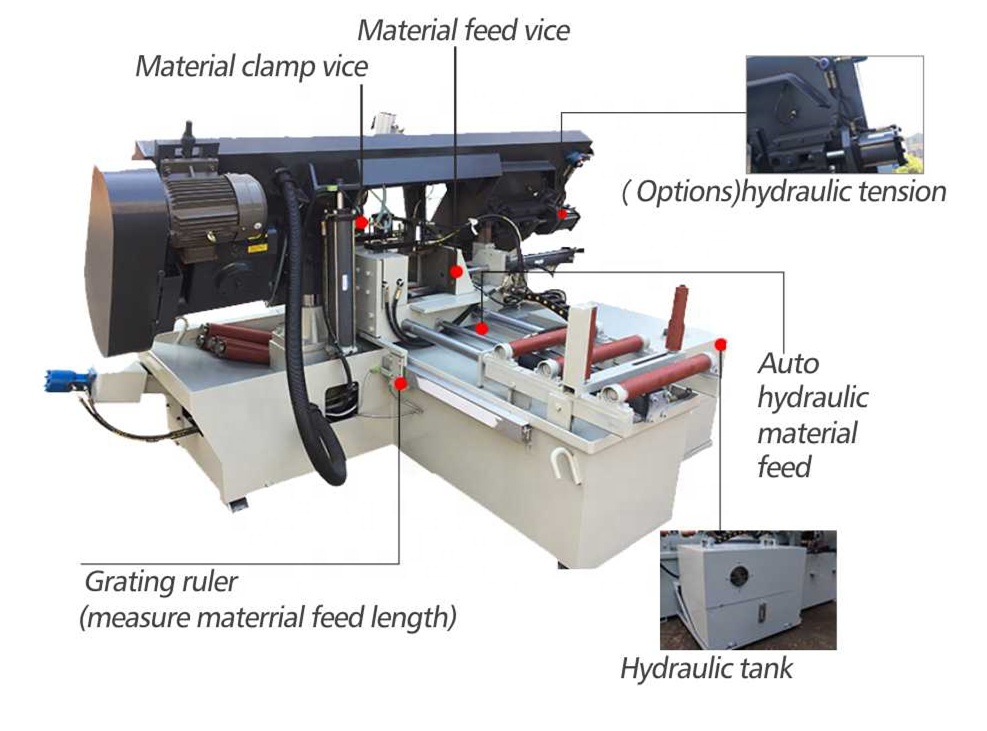

I. Structural components:

| Structural components: | commentate | Pictures for reference |

| auxiliary organizations | It includes feeding mechanism and guiding mechanism. The feeding mechanism can automatically transport the material to be processed to the sawing position, realizing continuous and efficient sawing operation; the guiding mechanism ensures the stability and accuracy of the saw blade in the sawing process, ensuring the sawing precision. |  |

| Lubrication system | It is mainly composed of oil tank and oil pump to provide lubrication for each moving part of the equipment, reduce friction and wear, and extend the service life of the equipment. |  |

| coolant system | Composed of water tank and water circulation pipeline, it cools the saw blade and workpiece during the sawing process, reduces the temperature of the blade, prevents the blade from overheating and affects the sawing effect and service life, and at the same time reduces the deformation of the workpiece due to the heat generated by the sawing and other problems. |  |

| safety device | For example, leakage protection switches, limiters, travel limit switches, etc., to protect the safety of operators and prevent accidents from occurring during the operation of the equipment. |  |

II.Functional features:

1. High degree of automation: it can realize a series of operations such as automatic feeding, clamping, sawing, unloading, etc. without manual intervention, which greatly improves the production efficiency and reduces the labor intensity of workers.

CNC operation: the operator can input sawing parameters through the CNC system, such as sawing length, sawing speed, feed, etc., the system can automatically carry out the sawing operation according to the set parameters, and the sawing precision is high, and the repeatability can reach ±0.1mm or even higher.

2. Wide range of application: it can be used for sawing various metal materials, such as carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, bearing steel and other ferrous materials, as well as some non-ferrous metals and non-metallic materials.

3. High efficiency and energy saving: due to the narrow kerf of the band saw, high cutting efficiency, compared with other cutting equipment, energy consumption is small, less material waste, with significant energy saving, material saving effect .

4. Easy to operate: the use of human-computer interface, such as touch screen, instead of the traditional control panel and buttons, all settings and operating information can be completed in the human-computer interface dialog box, the Chinese display, the operation is extremely simple.

5. High reliability: Equipped with various advanced detection and protection devices, it can monitor the running status of the equipment in real time, find and deal with faults in time to ensure the stable operation of the equipment.

III.Operation Steps.

1. Power on

Turn on the band saw machine power switch, wait for the equipment self-test is complete.

check whether the parameters on the display of the CNC system is normal, if there is any abnormality should be eliminated in a timely manner.

2. Programming

According to the workpiece processing requirements, enter the corresponding processing parameters in the CNC system, such as sawing length, feed speed, sawing times.

confirm that the programming is correct, save the program.

3. Clamping workpiece

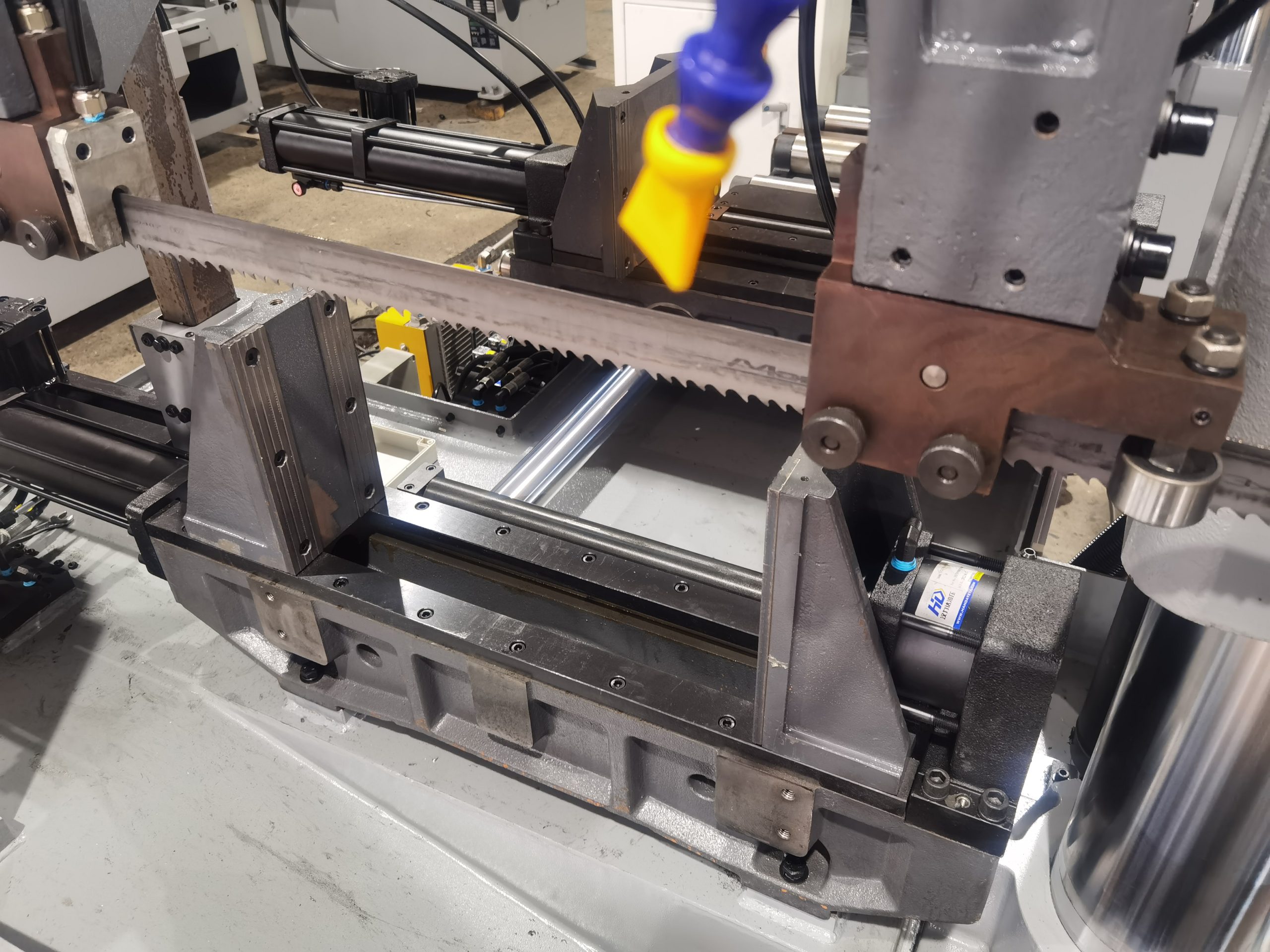

Place the workpiece on the table and use the clamping device to fix it firmly.

Make sure the workpiece is clamped reliably and will not move or loosen during sawing.

4. Start sawing

Press the start button and the band sawing machine starts to run automatically.

Observe the sawing process, pay attention to the operation of the saw blade, the injection of coolant and the processing status of the workpiece.

If there is any abnormality, press the emergency stop button immediately to stop sawing and carry out inspection and processing.

5. Processing is complete

When sawing is completed, the band sawing machine will automatically stop running.

Loosen the clamping device and remove the processed workpiece.

Check the machining quality of the workpiece and perform subsequent machining or processing if necessary.

Through the above we can see that the operation of fully automatic CNC band sawing machine is not particularly difficult. As long as the appropriate training and practice, the operator can master the operation method relatively quickly to ensure the normal operation of the equipment and processing quality.

If you also have the need to use fully automatic band sawing machine.Welcome to consult Shanghai ANTISHICNC Team. We are a senior supplier of band saws, with rich experience in manufacturing and utilizing machinery and equipment, and can provide you with professional technical support.