PCD saw blade laser processing center

PCD saw blade laser machine uses the high energy density of laser beam to irradiate the surface of PCD material. Photons destroy the diamond bond and convert the material into graphite phase. Then the graphite reacts with oxygen at high temperature and is removed in the form of gas, or directly sublimates and removes when the energy density is high enough. At the same time, the numerical control system accurately controls the movement trajectory, energy output, pulse frequency and other parameters of the laser beam, as well as the rotation and displacement of the saw blade, so as to achieve precise cutting, grinding, grooving and other processing operations on the PCD saw blade teeth. It is mainly used in the woodworking industry, stone processing industry, ceramic processing industry, and metal processing industry.

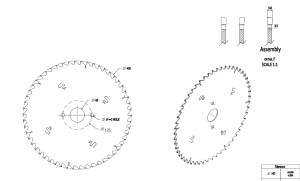

Customer drawings

Recently, ANTISHICNC team received an inquiry from a woodworking tool factory. The customer wanted to process a PCD saw blade with a diameter of 450. After carefully communicating the details and drawings with the customer, we recommended this six-axis laser processing center to him:

| Parameter | A360 PCD saw blade laser processing center |

| Movement travel X/Y/Z | 360mm×360mm×360mm |

| Three rotating axes | High-precision direct drive motor |

| X/Y/Z axis | linear motor |

| Maximum workpiece weight | 10kg |

| Maximum workpiece diameter | 500mm |

Fully enclosed protective cover (laser level 1)

With three active laser safety glass windows

Natural marble bed

With nanosecond laser, 1064 wavelength, average power 200Watt, 100mm focal length flat field lens

Remote control servo CNC system N3ET

Three linear mechanical axes, two optical axes control high-precision system

Three rotating axes.

Two optical axes, complete the actual processing of workpiece graphics.

If you have similar processing needs, please feel free to consult the Shanghai ANTISHICNC team. We will provide professional advice and help.

Keywords: PCD saw blade, laser processing center, saw blade cutting, woodworking industry, stone processing industry, ceramic processing industry, metal processing industry