Sawing and cutting automated production line to achieve the reuse of waste storage battery resources

With the increasing number of new energy vehicles, car batteries continue to increase, but the battery as a consumable, after the use of special equipment to deal with, and the current ordinary automotive used battery processing equipment to deal with used batteries, due to the degree of automation is not enough, it is often inevitable to require the operator to contact with all the parts of the battery, thus affecting the health of the operator, and in the process of processing In the process of treatment, the residue and waste liquid are not treated thoroughly enough, and it also pollutes the atmosphere and water body, which damages the ecological environment.

|

|

|

|

ANTISHICNC provides a waste battery treatment line that avoids contact between the operator and the battery, reduces the risk to the operator’s health, avoids pollution of the atmosphere and water, and realises the reuse of resources.

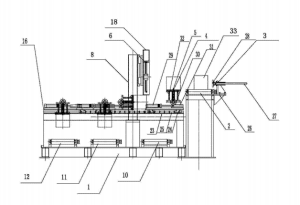

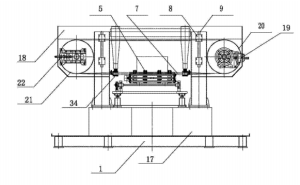

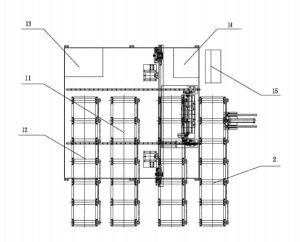

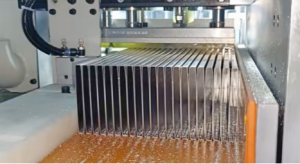

Structure composition:

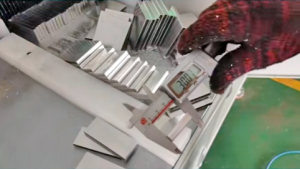

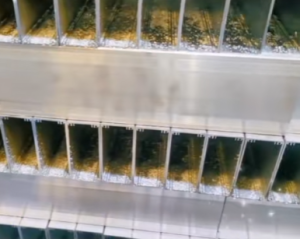

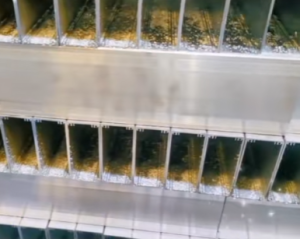

It includes a base, a battery input roller conveyor, a sawing machine, a hydraulic system, an electrical system, a sawing conveyor rail, a battery cover collection roller conveyor, a pole plate collection roller conveyor, a battery box collection roller conveyor, a servo turning trolley, and a battery push-in positioning device. Among them, the servo turning trolley is equipped with servo motors, synchronous belt wheels, synchronous belt, detection device and clamping device; sawing device for horizontal band sawing machine, including bed frame, column, saw frame, the main drive system, the active wheel, the driven wheel, band saw blade, hydraulic tensioning system and saw belt guiding device; sawing conveyor rail including guide rail, gears and racks, the guide rail is equipped with a limit of servo brakes; base is also equipped with a residual rinsing The base is also equipped with a residue rinsing device and a centralised waste liquid treatment device.

|

|

|

|

|

|

| 1. base,

2. Battery input roller conveyor, and 3. Battery push-in positioning device, and 4. Servo tipping trolley, 5. Clamping device 6. Sawing device 7. Band saw blade 8. Column 9. Lowering servo motor 10. Battery cover collecting roller conveyor, 11. Collecting roller conveyor for pole plates, 12. Battery box collecting roller conveyor, 13. Residue rinsing and recycling device, and 14. Hydraulic system 15. Electrical system 16. Sawing conveyor rail 17. Bed frame |

18. Saw frame,

19. Main drive system 20. Main Drive Wheel 21. Follower wheel 22. Hydraulic tensioning system 23. Guide rails 24. Gears 25. Rack and pinion 26. Fixing bracket 27. Push cylinders 28. Push rod, 29. Synchronous service motor. 30. Synchronous Belt Wheel 31. Synchronous Belt 32. Detecting Device 33. Batteries, 34. Saw belt guiding device. |

Working process:

The battery is manually placed on the battery input roller, and the battery is transported to the loading position before the battery push positioning device, and then pushed onto the servo flip trolley. The clamping device clamps the battery, and the servo flip trolley flips the battery and sends it to the sawing machine position of the horizontal band saw. The sawing machine performs sawing. After the sawing machine is finished, the battery cover falls into the battery cover collection roller, and the waste sulfuric acid automatically flows out into the waste liquid collection box; the servo flip trolley retreats, and flips again to make the battery plate fall into the plate collection roller, and then continues to retreat, the clamping device is released, and the battery box falls into the battery box collection roller; after the plate falls, the residue washing and recovery device washes the lead scraps in the shell, and the water and waste sulfuric acid after washing are treated by the waste liquid centralized treatment device. The entire process is controlled by the PLC system to achieve automated work.

Invention Advantage:

The sawing machine production line realizes the automation of waste battery processing from automatic loading, automatic positioning sawing, battery cover sorting and recycling, plate sorting and recycling, shell sorting and recycling, residue flushing and recycling, and waste liquid recycling, avoiding the operator’s contact with all battery parts and reducing the harm to the operator’s body. At the same time, it realizes the full recycling of residues and waste liquid, avoids pollution to the atmosphere and water bodies, and realizes the reuse of resources.

|

|

|

|

If you have metal sawing machine needs, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in metal sawing machine, can design the whole sawing production line for you, and provide you with professional technical support.

Keywords: sawing machine, scrap battery sawing, sawing line