Take you through the optimum and maximum sawing capacity of a sawing machine

When purchasing a new sawing machine for material undercutting, the user of the sawing machine should have a detailed understanding of the various properties of the band sawing machine and the difference between the maximum sawing width and the optimum sawing width.

The manual of the sawing machine explains that the equipment has the ability to saw 250mm of large material, let’s take a 250mm solid stainless steel material here and see if it can be sawed down, this is the same thing as to see if that new Volvo can actually continue to drive at 160 kilometers per hour is the same reason. In this article let’s identify what the terms maximum sawing capacity and opti

mum sawing capacity of a band saw machine actually mean.

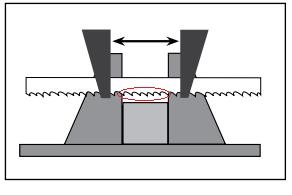

For each size of band saw blade, there is an optimum size of material that can be sawed: this size allows the band saw to cut quickly and provides good band saw life. This size is determined by the spacing of the guide blocks and the rigidity of the band saw blade. Anyone interested in the mechanical theory of saws will find them discussed in the topic of beam strength. Engineering applies a formula to this calculation, where the parameters include the deflection of the band saw blade, the modulus of elasticity, the moment of inertia, the load on the band saw blade, and the guide block spacing. It boils down to a simple statement that a 27mm band saw blade is suitable for sawing material between 100mm and 125mm wide, which is the optimum sawing width. The optimum size range will give you the maximum band saw blade life for a given size of band saw blade. When sawing in the optimum size range, a practically unskilled operator with a poor quality band saw blade will still be able to cut material without any problems. Sawing in the optimum size range means that many factors can be less demanding and still result in high quality workpieces and efficient downcutting.

BEAM STRENGTH: To calculate any beam strength difference, simply cube the band saw blade width and calculate the difference, taking into account the proportional change in band saw blade thickness. It is also important to consider the additional downforce required to cut wider kerfs due to increased band saw blade thickness.

Example:

Compare a band saw blade with 27mm*0.9mm to a band saw blade with 34mm*1.06mm (using 27mm as the standard unit):

27mm: 1 x 1 x 1 = 100%

34mm: (34/27) x (34/27) x (34/27) = 200%

Plus the increased strength from the 0.16 added thickness: 18%

Strength of a 34mm beam is 218% of the strength of a 27mm beam.

And so on:

Strength of 41mm*1.25 beam is 193% of 34mm*1.06;

The strength of a 54mm*1.6 beam is 256% of that of a 41mm*1.25;

The strength of a 54mm*1.6 beam is 123% of that of a 54mm*1.3;

The strength of 67mm*1.6 beam is 191% of 54mm*1.6;

The strength of 80mm*1.6 beam is 170% of 67mm*1.6

All of the above percentages are approximate and do not take into account the additional downforce required to increase chip widening.

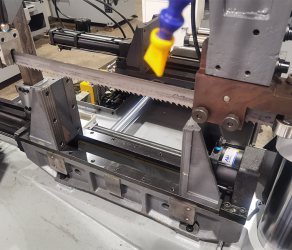

So let’s get back to our 250’s sawing machine and plan to cut that piece of 250mm solid stainless steel. A 27mm band saw blade was used on the sawing machine. According to the tooth spacing selection principle, it is best to use 2/3 TPI tooth spacing, use the right proportion of coolant, and it is also best to make the operator aware of the difference between grinding and sawing, and by the way, the sawing machine has to be in perfect running condition, and it is best for the tester to bring a lunch with him, because this material is more difficult to cut due to the physical properties of the material itself, and it will still take a certain amount of time to saw it down. Of course, the performance of the sawing machine determines the quality of the cut, the band saw blade is limited by the sawing machine, how much tension can be applied, and how it can be adjusted to the optimum position while sawing are all determined by the sawing machine, so in addition to the performance limitations imposed by the band saw blade specifications, the design and manufacture of the sawing machine is very important, a good quality 250 sawing machine can easily outperform other sawing machines with the same specifications of average quality.

However, even with the best quality sawing machines there is also the same limitation of the strength of the band saw blade itself, which prevents it from sawing larger materials beyond the strength of the band saw blade, and if larger materials are to be cut, higher strength saw blades should be used, which is the reason why sawing machines of different sizes are manufactured. The optimum saw size is selected to produce accurate workpieces, maximizing band saw blade life and productivity. When sawing down to material sizes equal to or close to the sawing machine’s maximum sawable size, band saw blade life and sawing efficiency may be reduced by as much as 50%, which is acceptable if used only occasionally, but if the sawing machine must be operated at its maximum sawing capacity for extended periods of time, even with high-performance band saw blades, and when the sawing machine is operated in optimum conditions and with a high level of operator skill, the following results can be expected The following results can be expected: long sawing times and short band saw blade life. This is just like driving a Volvo at 160 kilometers per hour for a long period of time, the driver will also get the following results: long jail time and short life.

The feed speed of the feeding system is also a matter of selecting the optimum feed speed, not the maximum feed speed. There are many factors that affect the operation of a band saw, for example, even if a skilled operator controls the saw, he may vary back and forth from optimum to maximum capacity even under ideal conditions. As a general rule, you will need to select the sawing machine and feed system best suited for your application. The capacity of the feed system is matched to the phase sawing machine and is designed to support the maximum size material that the sawing machine can saw that is being processed. The maximum design cut size is the largest size of material the sawing machine can cut, but this is not a realistic cut size for frequent use as large bar stock is often not straight and weight is concentrated in one area. The economic maximum is defined as the limit of sawing capacity that can be easily cut by the sawing machine. The optimum sawing capacity is the ability to easily cut into the material regardless of the surface condition or straightness of the material. As an analogy, if a half-ton truck reaches its design maximum, it can carry 2.5 tons or more; at its economic maximum, it can carry 1.2 tons; and at its optimum load, it can carry 0.5 tons, and if it exceeds the half-ton limit, the vehicle is difficult to start and difficult to stop.

Sawing Machine

|

|

|

|

Finished Product

|

|

In short, the choice of sawing machine should not be top-grade to choose, especially difficult to cut materials such as stainless steel, mold steel, titanium alloy, high temperature alloys and other materials, it is recommended to choose a large number of sawing machine and specification of a larger band saw blade, or else, the acquisition cost of the sawing machine is to save, but the subsequent operating costs will rise a lot of time to accumulate will be far more than the initial purchase of equipment to save costs.

If you have a sawing machine needs, welcome to contact the Shanghai ANTISHICNC team, we will have a dedicated docking to provide you with solutions.

Welcome to subscribe to our YouTube channel:

https://www.youtube.com/@antishicncmetalprocessingm9086/featured

Keywords: Sawing machine, Circular sawing machine, Machine tools