The application of sawing machines in various aspects of tower construction

In the field of modern architecture, tower buildings have become an important part of the city’s skyline and infrastructure with their unique functions and iconic appearance. From the towering transmission towers that build “air bridges” for power transmission to the rising communication towers that allow information to be transmitted unimpeded, the birth of each tower is inseparable from the collaborative operation of many precise and efficient construction equipment. The sawing machine, a seemingly ordinary tool with huge energy, plays an extremely critical role in the entire process of tower construction. Its wide application and important role are beyond imagination.

Sawing machines have many applications in tower construction, and the following are some of the main aspects:

Cutting structural steel

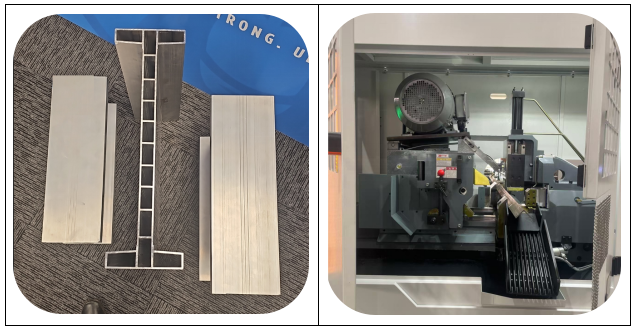

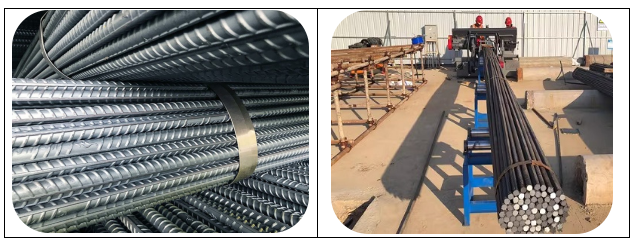

In tower construction, a large number of structural steels of various specifications are used to build the frame of the tower body and other structures. Sawing machines can cut long steel into specific lengths and angles according to design requirements. For example, for transmission towers, angle steels, channel steels, etc. need to be cut into suitable lengths for assembling towers. Sawing machines can ensure the dimensional accuracy of steel through precise cutting, ensuring the stability and accuracy of the tower structure.

For some large communication towers, their supporting structures may require the use of thick-walled steel pipes. Sawing machines can use suitable saw blades to cut these steel pipes to meet the needs of different heights and structural layouts.

Processing tower parts

Some parts in tower construction, such as node plates and stiffeners, usually need to be cut from plates or profiles. Sawing machines can cut materials such as steel plates and aluminum plates to provide blanks for the processing of these parts. For example, when building a TV tower, the bracket parts used to fix equipment can be cut from the steel plate by a sawing machine, and then the subsequent drilling, welding and other processing procedures can be carried out.

Some decorative parts or small structural parts of the tower may also need to be cut by a sawing machine. For example, some uniquely shaped metal parts on the landscape tower can be precisely cut by a sawing machine to achieve the shape and size required by the design, adding characteristics to the appearance of the tower.

Cutting foundation piles

The foundation of the tower usually requires piles to provide stable support. The sawing machine can be used to cut concrete piles, steel piles, etc. In the construction of bridge tower foundations, it is often necessary to cut the precast concrete piles to a suitable length to adapt to different geological conditions and foundation design requirements.

For some offshore wind power towers, their foundation piles may be large steel pipe piles. The sawing machine can perform end cutting and groove processing on the steel pipe piles during the manufacturing and installation process to ensure the connection quality between piles and between piles and foundation caps.