What are the advantages of metal circular sawing machine compared with metal band sawing machine?

With the upgrading of industrialization, more and more processing enterprises choose metal circular sawing machine instead of traditional band sawing machine, many people may have such doubts: what are the advantages of circular sawing machine compared with band sawing machine? Next, I will analyze the similarities and differences between the two, and you may understand after reading it.

1.Production efficiency:

Fast cutting speed: The metal circular sawing machine usually has a high rotation speed, and the saw blade rotation speed is fast, which can quickly cut metal materials. In general, its cutting speed is much higher than that of metal band sawing machine, which is several times or even higher than the working efficiency of traditional band sawing machine. For some enterprises that need a lot of cutting work, the production cycle can be greatly shortened and the production efficiency can be improved.

Strong continuous operation ability: The structure and working mode of the circular saw machine make it perform better in continuous operation, and can carry out cutting work stably for a long time, reducing the downtime and adjustment time of the equipment, and further improving the production efficiency.

2.Cutting accuracy:

High stability of the saw blade: The saw blade of the metal circular saw machine is round, and in the design of the equipment, the saw blade is usually better reinforced and stable, and it is not easy to swing during the cutting process. The saw blade of the band sawing machine may swing due to various factors when cutting, and its accuracy is relatively limited.

Good incision quality: the incision after cutting by the circular saw machine has high flatness, less burrs, and more guaranteed dimensional accuracy. The cut workpiece does not need to undergo too much post-processing, which can meet the high quality requirements, saving the time and cost of post-processing.

3.Operability:

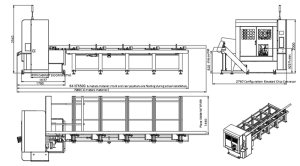

High degree of automation: most of the modern metal circular sawing machines use CNC automatic control, the operator only needs to set the values and parameters when starting the machine, and the equipment can automatically complete the cutting process, without the need for the operator to be stationed next to him at all times, observe the sawing situation and place the processing workpiece. This not only reduces the labor intensity of the operator, but also improves the consistency and stability of production.

Easy to operate: The operation process of the metal circular saw machine is relatively simple, and the operator only needs to master the basic operation methods and parameter settings to carry out efficient cutting work. In contrast, the operation of a band sawing machine tests the experience and skill of the operator to ensure the quality and safety of the sawing.

4.Maintenance Costs:

Long service life of saw blades: The material and manufacturing process of the saw blade of the circular saw machine are continuously improved, with high wear resistance and fatigue resistance, and a long service life. Moreover, the saw blade of the circular saw machine is relatively easy to replace, and the replacement cost is relatively low. The saw blade of the band saw machine is more easy to wear and break, and needs to be replaced frequently, the price of the band saw blade is relatively high, and the maintenance cost is high.

Good equipment stability: the structure of the circular saw machine is relatively simple, the wear and failure rate of mechanical parts is low, the stability of the equipment is good, and the maintenance work is relatively less. The structure of the band sawing machine is more complex, involving multiple components such as saw wheels, saw blade tensioning devices, and guide devices, which are prone to failure during long-term use and require regular maintenance and overhaul.

Scope of application:

Strong adaptability to materials: The metal circular sawing machine can choose different saw blades according to different materials and cutting requirements, and is suitable for cutting metal materials of various shapes and sizes, including round pipes, square pipes, special-shaped pipes, etc. For some metal materials with high hardness and complex shapes, the circular saw machine can also be effective for cutting.

Good adaptability to the environment: the circular sawing machine produces relatively less noise and dust when working, and the pollution to the working environment is less. Moreover, the circular sawing machine is relatively small in size and occupies a small area, which is more suitable for some production sites with limited space.

In general, the enterprise has a large production volume and high requirements for the quality of the workpiece, which is more suitable for circular sawing machines; If the material accuracy requirements of its cutting are general, and the diameter of the workpiece is relatively large, it is more suitable for metal band sawing machines, and the specific choice needs to be based on the actual maximum needs of the enterprise.

If you also need a suitable high-speed circular saw or metal band sawing machine.Welcome to consult Shanghai ANTISHICNC Team. We are a senior supplier of band saws, with rich experience in manufacturing and utilizing machinery and equipment, and can provide you with professional technical support.