What does the throat depth of a metal vertical band saw refer to and what is its function

The throat depth of a vertical saw refers to the distance from the saw blade to the bed, specifically, the size of the workpiece that needs to be sawed. This size is specified based on the customer’s actual sawing situation, so most vertical band saws are non-standard custom saws. In practical applications, the size of the throat depth directly affects the size of the workpiece that the saw can handle, and is an important parameter in the design and use of vertical saws.

The main role of the throat depth:

The embodiment of processing capabilities

The size range of workpieces that can be sawed

1.Determine the maximum sawing diameter: The throat depth directly limits the maximum diameter of the circular workpiece that can be sawed on the saw. For example, a saw with a throat depth of 500 mm can theoretically saw circular workpieces with a diameter of no more than 1000 mm.

2.Affect the size of rectangular workpieces: For rectangular workpieces, the throat depth determines the width that can be sawed. For example, a saw with a throat depth of 400 mm can saw rectangular materials with a width of less than 800 mm.

Adapt to diverse processing needs

1.Meet the needs of different industries: In the machinery manufacturing, construction, automobile and other industries, metal materials of various sizes often need to be processed. Sufficient throat depth allows the sawing machine to adapt to the sawing of various materials such as larger-sized steel in the construction industry and medium and large shaft parts in machinery manufacturing.

2.Flexible processing of special-shaped workpieces: When encountering special-shaped workpieces such as fan-shaped and semi-circular, a larger throat depth can provide more operating space and facilitate sawing from a suitable angle.

Operational convenience and efficiency

Convenient clamping and positioning of workpieces

1.Provide sufficient operating space: The larger throat depth allows workers to have more space when clamping workpieces, making it easier to adjust the position of the workpiece, ensuring that it is correctly aligned with the saw blade, and reducing sawing errors caused by improper clamping.

2.Adapt to complex clamping needs: For some workpieces that need to be fixed with special clamps or multiple sets of clamps, sufficient throat depth can accommodate these clamps, making the clamping process smoother.

Improve sawing efficiency

1.Reduce the number of workpiece adjustments: When the throat depth is sufficient, multiple smaller workpieces can be clamped at one time for batch sawing, without frequent workpiece replacement and re-clamping, thus saving time and improving production efficiency.

2.Convenient for continuous sawing of long materials: When sawing long metal materials, the larger throat depth allows the material to be placed more steadily on the workbench during the sawing process, reducing the shaking caused by the material extending too long, ensuring the continuity and stability of the sawing, and thus improving efficiency.

Choosing a suitable metal vertical band saw to meet specific processing needs requires comprehensive consideration of multiple factors. Here are some key points:

Processing material characteristics

Material hardness

1.Materials with lower hardness: For non-ferrous metals such as aluminum and copper, general medium and low power band saws can meet the sawing needs. You can choose a saw with a relatively high blade linear speed to improve sawing efficiency.

2.Materials with higher hardness: For alloy steel, hardened steel, etc., you need to use a saw with higher power and slower blade feed speed, and at the same time, you need to match it with high-quality saw blades suitable for sawing hard materials, such as bimetallic saw blades or carbide saw blades.

Material shape and size

1.Smaller materials: If you mainly process small bars, pipes or profiles, a saw with a relatively small throat depth can do the job, such as a saw with a throat depth of 300-500mm, and you can choose a saw with a narrower blade width to reduce material waste.

2.Large materials: For large billets, thick plates, etc., you need a saw with a larger throat depth, such as a throat depth of more than 800mm. At the same time, you need to consider the table size and load capacity of the saw to ensure that large workpieces can be stably placed and sawed.

Sawing accuracy requirements

1.Rough processing: For occasions where the sawing accuracy is not high and the sawing efficiency is the main concern, such as cutting blanks, you can choose a band saw with ordinary precision, which is relatively cheap and can meet the basic sawing function.

2.Finishing: If it is used to process precision parts, such as parts in aerospace and precision machinery manufacturing, you need to choose a high-precision band saw. This type of sawing machine usually has a more precise guide device, feed system and control system, which can ensure the flatness, verticality and dimensional accuracy of the sawing surface.

Production efficiency requirements

1.Batch production: If it is a large-scale batch production, you should choose a band saw with a high degree of automation, such as a saw with an automatic feeding device, an automatic clamping device and an automatic cutting cycle function, which can greatly improve production efficiency and reduce labor costs.

2.Small batch or single piece production: For small batch or single piece production, manual or semi-automatic sawing machines may be more suitable, with relatively flexible operation and a more affordable price. While meeting processing needs, it can reduce equipment investment costs.

Budget and cost

1.Equipment procurement cost: Under the premise of meeting the processing needs, choose a suitable sawing machine according to your own economic strength and budget. Generally speaking, the more complex the function, the higher the precision, and the higher the degree of automation of the sawing machine, the higher the price.

2.Use and maintenance cost: In addition to the purchase cost, the use and maintenance cost of the sawing machine should also be considered, including the consumption of saw blades, power consumption, equipment maintenance, etc. For example, although some high-end sawing machines have high purchase costs, they have long saw blades and low energy consumption, which may be more cost-effective in the long run.

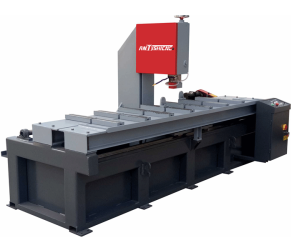

The following are the vertical saw models selected by our Singapore customers for cutting aluminum plates

| Model Name | CV-5080 | |

| Max.cutting capacity | Height | 500mm |

| Throat | 800mm | |

| Length | 3000mm | |

| Saw blade | Speed | 800-1600m/min (Inverter) |

| Size | 41×1.3 | |

| Tension | Hydraulic | |

| Guides | Carbide guiding blocks | |

| Cleaning | Wire brush & flood coolant | |

| Motor output | Blade | 15kw |

| Hydraulic | 0.75kw | |

| Coolant | 60w | |

| Feed | 0.85kw (SERVO MOTOR) | |

| Vice | T-slotted table, manual clamping blocks by user | |

|

||

| Customer workpiece actual picture/aluminum plate | cutting method | |

|

|

|

If you also need a suitable metal vertical sawing machine,Welcome to consult Shanghai ANTISHICNC Team. We are a senior supplier of band saw machine, with rich experience in manufacturing and utilizing machinery and equipment, and can provide you with professional technical support.

Keywords: Vertical sawing machine, Metal vertical sawing machine, Large vertical band sawing machine