What kind of band saw is more efficient for seamless pipes of different diameters?

Seamless pipes of different diameters, in order to improve cutting efficiency and rational use of the machine. We generally adopt two ways to cut;

For materials with larger diameters, use single pipes for cutting;

For pipes with smaller diameters, use bundles for cutting.

Bundle cutting is a material processing technology that involves cutting a bundle or a bundle of long strips of material (such as metal bars, pipes) into multiple shorter sections at the same time. This cutting method is often used to improve production efficiency and reduce processing time because it allows multiple materials to be cut at one time instead of cutting each one individually.

Two ways of bundling

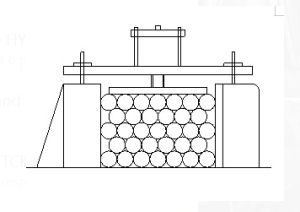

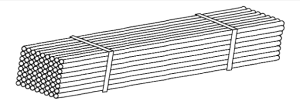

One is mechanical bundling: the pipes/bars are already bundled, just measure the bundle size and choose the appropriate machine to cut;

The second is manual bundling: the pipes need to be stacked one by one manually, which will involve the problem of feeding. Will the manually stacked pipes slip during feeding, resulting in uneven length of materials during cutting? In this case, we recommend using a sawing machine specially designed for bundle cutting to perform fixed cutting, which will have a better effect.

Bundle cutting also involves a problem, which is corner bundle cutting; if it is a bundle that has been bundled, just choose the appropriate angle to cut; for manual bundling, it is not recommended to stack too many small-diameter pipes.

| Manual bundling model |

|

| Mechanical Bundling Model |

|

Recently, Shanghai ANTISHICNC Machine received an inquiry from a customer in Kosovo. The customer wanted to cut seamless pipes ranging from 12.7mm to 101.6mm and required 45°angle cutting.

According to the customer’s requirements, we selected the GZ4250H (straight cutting) fully automatic straight cutting metal band saw for bundle cutting and used with our BS-712N (45° rotating angle). The specific parameters are as follows:

| Model | GZ4250H | |

| Max.cutting capacity | Round | 500mm |

| Quadrate | 500×600mm | |

| Saw blade | Speed | 40/55/70/90 m/min |

| Size | 41×1.3×5700 | |

| Guides | Carbide and bearing blade guides | |

| Cleaning | Wire brush & flood coolant | |

| Tension | Manual | |

| Motor output | Blade | 5.5kw |

| Hydraulic | 1.5kw | |

| Coolant | 0.12kw | |

| Multiple feeding | 500mm×10times | |

| Work Vice | Hydraulic | |

| Machine size | 2850×2250×1960mm | |

|

||

| Model | BS-712N | |

| Max.cutting capacity | Circular @ 90°Round steel | 178mm(7”) |

| Rectangular @90°Square steel | 178x305mm(7”x12”) | |

| Circular @45°Round steel | 127mm(5”) | |

| Rectangular @45°Square steel | 120x125mm (4.75”x4.88”) | |

| Blade speed | @60Hz | 27,41,59,78MPM |

| @50Hz | 22,34,49,64MPM | |

| Blade size | 19×0.9x2362mm | |

| Motor power | 750W 1HP(3PH), 1.1KW 1.5HP(1PH) | |

| Drive | V-belt | |

| Packing size | 125x51x114cm | |

| N.W./G.W. | 140/180kg | |

|

||

If you also need to cut seamless pipes of different diameters and choose the right band saw, please consult Shanghai ANTISHICNC Machine. We are a senior supplier of metal machining equipment, with rich experience in manufacturing and using mechanical equipment, and can provide you with professional technical support.

Keywords: Fully automatic metal straight cutting band saw machine, metal cutting saw machine, angle band saw machine